In the United States, a structure fire is reported approximately every 65 seconds, according to the National Fire Protection Association. While sprinklers, alarms, and evacuation plans are critical, one of the simplest yet most effective defenses against fire and smoke spread is a properly installed fire-rated door.

These doors are built to contain fire and smoke within a designated area for a specified period, giving occupants vital time to evacuate and allowing firefighters to respond effectively.

In commercial facilities, whether offices, warehouses, or healthcare centers, meeting fire-rated door requirements is more than a best practice; in many cases, it’s a legal obligation under building and fire codes.

With this blog, we’ll help you understand the basic, but essential, fire-rated door requirements so that your facility can be safe and secure.

Understanding Fire-Rated Door Ratings

Fire-rated door requirements are based on how long a certified door assembly can withstand fire exposure, commonly 20, 45, 60, 90, or 180 minutes. These durations indicate how long the door can maintain integrity and limit smoke and heat passage under standardized test conditions.

Fire Protection Rating vs. Fire Resistance Rating:

- Fire Protection Rating (doors) measures the assembly’s ability to prevent fire and smoke spread.

- Fire Resistance Rating (walls/barriers) measures the wall’s ability to maintain structural integrity during a fire.

In the U.S., testing follows standards such as UL 10B, UL 10C, and NFPA 252. For example, a 90-minute fire-rated door in a two-hour-rated wall is typical for stairwells or hazardous storage rooms, aligning with established fire-rated door requirements.

Placement Requirements for Fire-Rated Doors

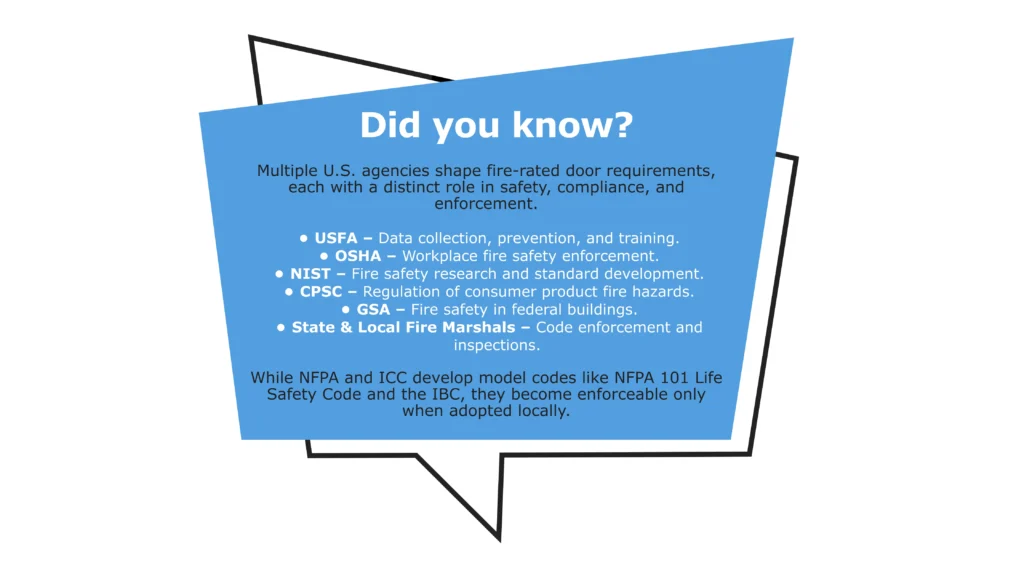

The Occupational Safety and Health Administration (OSHA) requires that commercial and industrial workplaces maintain exits protected by fire-rated barriers and assemblies that comply with recognized standards.

Common locations for doors that must meet fire-rated door requirements include:

- Exit stairwells – Blocking fire and smoke from escape routes.

- Exit corridors – Preserving safe evacuation pathways.

- Hazardous content rooms – Electrical, boiler, or chemical storage.

- Between occupancies – Separating zones with different fire risks.

Moreover, in residential settings such as condo buildings, apartments, complexes, etc, local codes often require fire-rated doors between garages and living spaces, or in multifamily building corridors.

Now that you’re familiar with fire-rated door ratings and where they should be placed in your facility, let’s dive into one of their most critical aspects: the material requirements.

Core Construction and Material Requirements

To meet fire-rated door requirements, the entire assembly, door leaf, frame, glazing, seals, and hardware must be constructed from materials tested and approved for fire resistance. Commonly used materials include:

- Steel – A durable, non-combustible option ideal for commercial and industrial environments, providing high strength and stability under heat.

- Fiberglass-reinforced composites – Engineered for dimensional stability, these resist warping or swelling under temperature and humidity changes while delivering consistent performance.

- Solid-core wood with fire-resistant layers – Often specified in architectural settings where aesthetics matter, these are constructed with non-combustible cores and protective facings to achieve required ratings.

In addition to the door leaf material, compliant assemblies often incorporate:

- Intumescent seals that expand under heat to block flames and smoke.

- Fire-rated glazing that allows visibility while maintaining thermal and smoke resistance.

- Compatible hardware—locks, latches, closers, and hinges—tested as part of the door system.

Per NFPA 80 and related standards, every component must be individually labeled and certified as fire-rated, ensuring the entire assembly functions as a single, tested unit.

Integrated Door Systems & Performance Features

Modern fire-rated door models are designed as integrated systems, where hardware, locking mechanisms, and control points are built into the door itself. Common configurations include:

- Exit device-operated doors with mortise lock functionality for safe, fast egress.

- Lever-operated doors that combine conventional lockset familiarity with advanced security and fire performance.

- Pushpad-operated doors for single-motion egress without compromising aesthetics.

- Automatic flush-bolt panels for securing inactive leaves in paired door systems without visible floor strikes or manual bolts.

These systems are engineered to meet rigorous performance benchmarks, including:

- Fire/smoke ratings for openings up to 8′-6″ x 10′-0″.

- UL 10B/UL 10C fire tests and UL 1784 air leakage compliance.

- NFPA 252 fire door testing standards.

- ADA and ANSI/BHMA accessibility and hardware durability requirements, respectively.

Aesthetic and Functional Enhancements

In high-traffic or design-sensitive environments, fire-rated doors can be customized with:

- Multiple architectural finishes such as satin stainless steel, dark bronze, polished brass, or powder-coated colors.

- Antimicrobial coatings for healthcare, education, or germ-sensitive facilities.

- Concealed hardware and flush latching systems to maintain clean sightlines and reduce tampering risks.

By combining certified materials, integrated hardware, and code-compliant installation, a fire-rated door assembly not only meets life-safety requirements but also delivers long-term durability, ease of use, and visual harmony with the surrounding space.

Door Frame and Assembly Standards

Fire-rated door requirements cover the entire assembly, not just the slab. NFPA 80 specifies:

- No open holes or unauthorized field modifications.

- Secure, undamaged frames.

- Hardware that does not impede emergency operation.

Failing to meet these assembly-level requirements can void certification and lead to inspection failures from a State or Local Fire Marshal’s Office.

Testing and Certification Requirements

To meet fire-rated door requirements, assemblies undergo rigorous testing:

- Endurance Test – Exposure to up to 1925°F for the rated period.

- Hose Stream Test – Measures resistance to impact and cooling (required in Canada for all ratings, optional for U.S. 20-minute doors).

- Temperature Rise Test – Evaluates heat transfer control.

Testing agencies like UL and Intrtek apply permanent labels showing the door’s certified rating.

Installation, Inspection & Maintenance: The GS Parcel Advantage

At GS Parcel, we go beyond simply supplying fire-rated doors; we ensure every installation is code-compliant from day one and stays that way for years to come.

Following NFPA 80 standards, our process covers:

- Manufacturer-Compliant Installation – Our certified, in-house team (no middlemen) handles fitment, alignment, and hardware integration so each door operates flawlessly and meets UL requirements.

- Annual Compliance Inspections – We help property managers, contractors, and facility operators stay inspection-ready with yearly checkups in line with NFPA 80 guidelines.

- Proactive Issue Correction – From removing wedges that keep doors open, replacing damaged seals, and restoring missing self-closers to preserving fire-label visibility, we address the most common violations before they become fines or safety hazards.

- Post-Install Compliance Check – Every project concludes with a detailed review to confirm doors latch, close, and seal as intended.

With UL-certified products, a full range of styles (solid-core, glass panels, or vision inserts), and responsive service built around your schedule, we make it easy to safeguard your facility, pass inspections, and avoid costly legal or corrective action.

Now that we’ve covered the essentials, here’s a quick self-audit checklist to see if your fire-rated doors are truly inspection-ready.

Quick-Reference Fire-Rated Door Requirements Checklist

1. Door Rating & Certification

- Door has a permanent fire rating label from a recognized testing agency (e.g., UL, Intertek).

- Rating matches the wall/barrier rating per code (20, 45, 60, 90, or 180 minutes).

- Entire assembly (door, frame, hardware, glazing) is fire-rated.

2. Placement & Code Compliance

Fire-rated doors installed in all required locations:

- Exit stairwells

- Exit corridors

- Hazardous content rooms

- Between occupancies

- Garage-to-living space transitions (residential)

- Placement complies with local building/fire codes.

3. Construction & Materials

- Door material meets Fire-Rated Door Requirements (steel, fiberglass, or solid-core wood with fire-resistant layers).

- Intumescent seals are installed and intact.

- Fire-rated glass in vision panels is labeled and tested.

4. Installation & Hardware

- Installed per manufacturer and NFPA 80 guidelines.

- Self-closing and self-latching hardware functions properly.

- No field modifications that compromise rating (extra locks, drilled holes, etc.).

5. Clearance & Fit

- Clearance gaps meet NFPA 80 limits (max ¾” under door; ⅛” at top/sides).

- Door closes tightly without binding.

6. Maintenance & Inspection

- Door operates without obstruction; not propped open.

- Labels are visible and not painted over.

- Annual inspection completed and documented.

- Repairs performed by certified personnel when needed.

7. Documentation & Records

- Inspection and maintenance logs up-to-date.

- Code compliance documentation available for inspectors.

Note: If any box above is unchecked, the door may fail inspection or violate fire-rated door requirements, exposing your facility to safety risks and fines.

Ensure Your Building Meets Fire-Rated Door Requirements with GS Parcel

Understanding the requirements is one thing; ensuring every opening in your facility is truly compliant is another. Therefore, when you partner with GS Parcel, you get access to UL-certified fire-rated door assemblies meeting NFPA 80, IBC, and tested to UL10B, UL10C, and UL1784.

Moreover, we deliver solutions from 20-minute to 90-minute ratings, tailored to occupancy, wall ratings, and code mandates. Our process includes:

- Site assessments to pinpoint compliance needs.

- Product sourcing aligned with your fire protection plan.

- Certified in-house installation; no subcontractor delays.

- Post-install compliance checks ensure each door seals, latches, and operates as required.

- ADA and access control coordination.

Don’t risk inspection failures.

Call us at (866) 233-3597 or book your site consultation today to ensure full compliance with all fire-rated door requirements.

References

- https://www.maine.gov/dps/fmo/sites/maine.gov.dps.fmo/files/inline-files/2021HomeFire%20LossFireLoss.pdf

- https://www.nfpa.org/news-blogs-and-articles/blogs/2021/02/12/how-to-determine-the-required-fire-protection-rating-of-an-opening-protective

- https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.36

- https://www.intertek.com/building/standards/nfpa-80/

- https://colab.research.google.com/drive/1jMDwX8i8WN27w9A9BdJp2mqDwW9A2y9B

- https://www.intertek.com/building/standards/ul-10c/

- https://www.intertek.com/building/standards/ul-1784/

- https://www.intertek.com/building/standards/nfpa-252/

- https://www.access-board.gov/ada/guides/chapter-4-entrances-doors-and-gates/

- https://blog.ansi.org/ansi/nfpa-80-2019-standard-fire-doors/

- https://buildershardware.com/LinkClick.aspx?fileticket=zulQ0fYkVgY%3D&portalid=0×tamp=1730489890369

- https://www.ul.com/resources/fire-test-standards-and-certifications-fire-doors

- https://www.intertek.com/building/markets/fire-door/